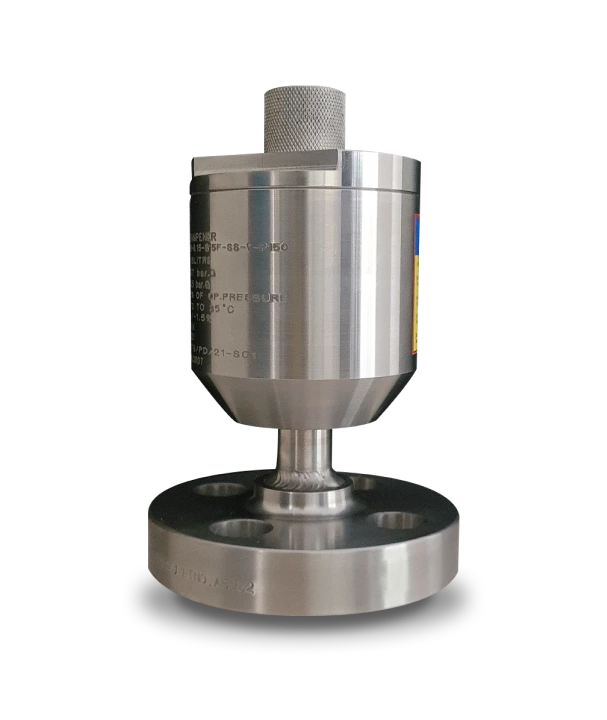

Pulsation Dampener

Pulsation dampener is a device that is used to absorb the pressure spikes generated during the working of reciprocating pumps in the hydraulic circuits. It is also acting as a leakage compensator, shock absorber, energy storage device as well.

Features

- Vigorous build with highly chemical resistant FKM material that ascertains durability against high temperatures

- Exhibits impeccable gas holding capacity using its non-return valve

- Extends high degree safety against high pressure through ASME Sec VIII design

- Includes Universal Charging Kit comprising pressure gauge, adaptors, and spare seals held intact within a carrying case