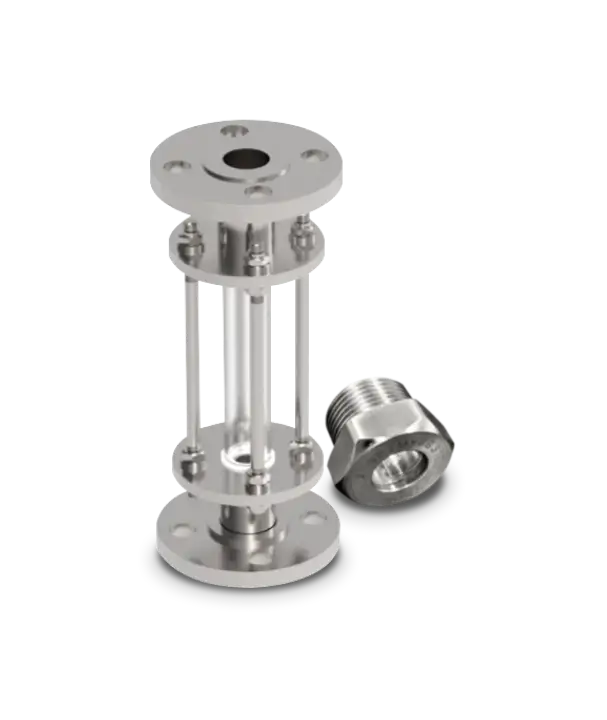

Sight Glass & View Glass

Sight Glass is used for visually ensuring the flow / presence or absence of process fluid in the piping system and they provide direct visual confirmation of the process fluid and lines in the direction of the flow path of the fluid. View glasses are used to monitor the oil level in the tanks / Panels and similar vessels. It is a direct visual level indicating device.

Features

- Direct visual indication

- 360° visibility (Sight glass)

- Materials suitable for any service available

- PTFE Sealant used to avoid leakage and corrosion