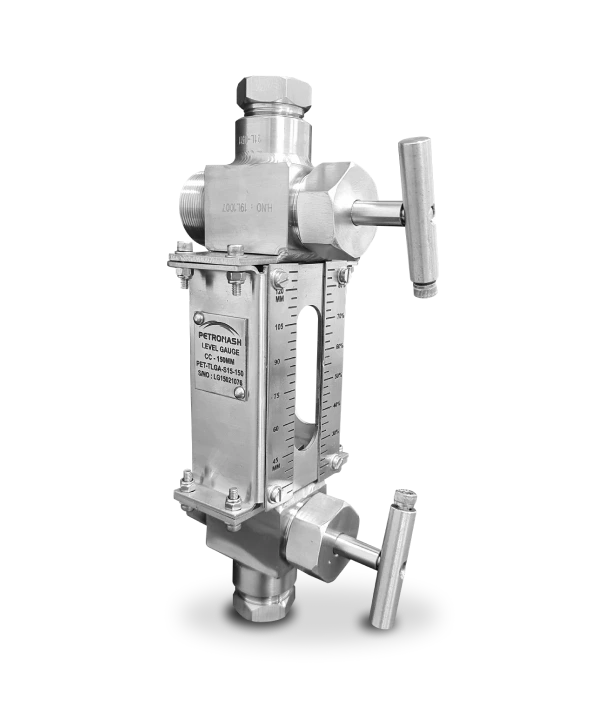

Tubular Level Gauge

Tubular Level Gauge or Level Indicator is a simple, yet effective device that helps in measuring direct reading of liquid levels in atmospheric tanks, pressurized tanks, panels and similar vessel.

This is connected with the tank in parallel through thread or flanged connection so that the tank liquid seeks out to the gauge indicator. It comprises a glass or acrylic tube, Gauge Valves with ball check arrangement and Tube Protection Guards with 360-degree visibility.

Features

- Direct level measurement

- 360° visibility

- Ease of tube replacement

- Dual Sealant (PTFE & VITON) used to avoid leakages